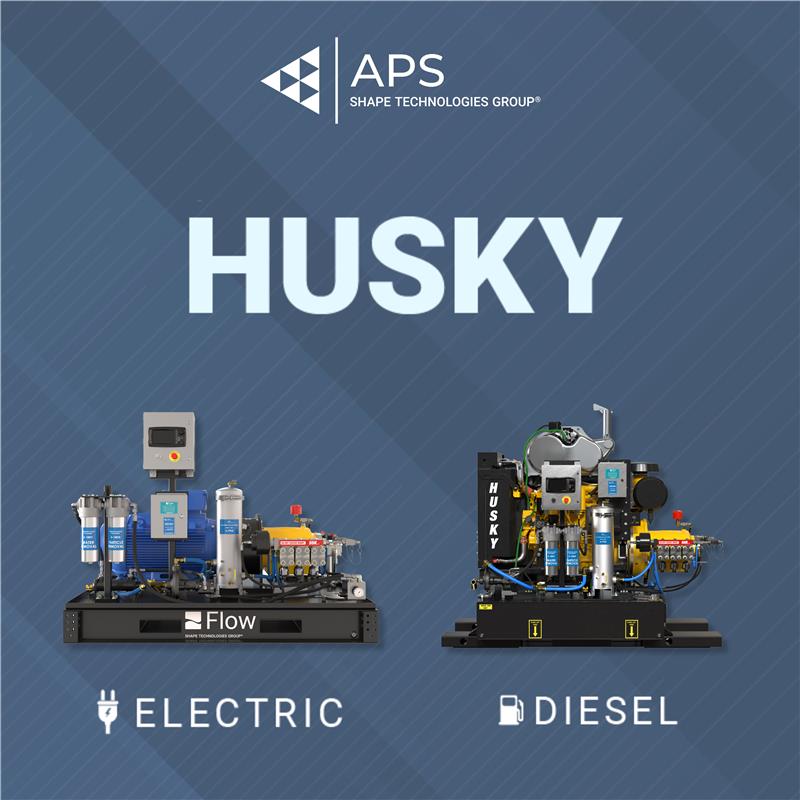

The 55k Husky - A Surface Preparation Leader

Since its introduction in the 1990s, the Husky has become an industry leader in industrial surface preparation for many industries and applications. This blog will highlight some of the Husky 55k's differences and advantages over the current market.

When it comes to pump technology, the choice between stroke length and bore size has long been a pivotal consideration. The traditional approaches often leaned towards a slower, longer stroke paired with a larger bore, which is perceived to offer optimal performance.

However, we embrace a shorter, faster stroke integrated with an External Control Valve (ECV). This innovative combination empowers the pump to efficiently expel all unused water directly at pressure, a capability absent in other conventional models. The Husky maximizes efficiency without sacrificing performance by opting for a shorter, faster stroke. This streamlined approach reduces cycle times and keeps horsepower and torque levels, yielding substantial cost savings over time. Moreover, incorporating the ECV ensures prompt expulsion of all unused water at pressure, mitigating backflow and optimizing pump functionality.

Secondly, competitors have traditionally favored a bypass valve and a large tumble box setup, allowing water to be dumped at the gun or the tumble box. However, this approach places excessive strain on the dump valve, leading to frequent replacements and increased maintenance expenses. In contrast, the Husky is designed to dump all the excess water directly at the pump and only needs a compact tumble box that minimizes maintenance requirements and enhances maneuverability during idle periods. Additionally, the Husky's direct water dumping mechanism significantly reduces wear, surpassing the lifespan of bypass valves utilized by competitors.

Another feature that distinguishes the Husky is its superior pressure stability during operation. It outperforms all competitors not only in static conditions but also at full flow. Operators are able to utilize three guns at maximum flow, and the Husky will consistently maintain the designated pressure. In comparison, most competing pumps experience a significant drop in pressure under similar conditions. For instance, when set to 40,000 PSI, the actual pressure during operation may plummet to 36,000 or 37,000 PSI. This decline adversely impacts production rates, necessitating additional time and expenditure.

The APS Husky's unparalleled pressure stability not only enhances operational efficiency and contributes to cost savings but also minimizes downtime and optimizes production rates. This reliability in demanding industrial environments is a testament to the superior performance and trustworthiness of the Husky pump.

Finally, the Husky boasts a 180-gallon tank that allows for roughly 12 hours of continuous use. This enables uninterrupted production throughout an entire shift without refueling interruptions, which further lowers costs.